Precision cutting has undergone a revolution because of water jet cutting technology, which provides unmatched efficiency, accuracy, and versatility. Businesses and industries in Ipswich are using water jet cutting to reliably and precisely satisfy their varied cutting needs. Now let's explore the special benefits and uses of Ipswich water jet cutting services:

Minimal Material Distortion:

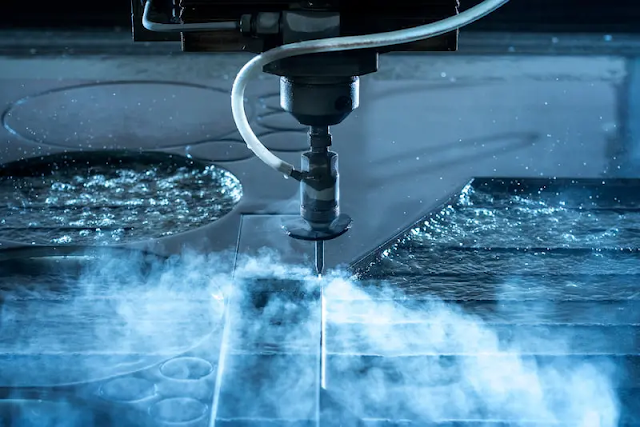

Unlike traditional cutting methods that generate heat and produce thermal distortion, water jet cutting operates at room temperature, minimising the risk of material deformation or damage. This is particularly beneficial for cutting heat-sensitive materials or intricate designs where precision is paramount. By preserving the integrity of the material, water jet cutting ensures that the finished products meet the highest quality standards.

Complex Shape Cutting:

Water jet cutting excels at cutting complex shapes and intricate patterns with unmatched accuracy and detail. Whether it's intricate designs for architectural features, precise components for machinery, or intricate signage for branding purposes, water jet cutting can deliver results that meet the most demanding specifications. This capability allows businesses in Ipswich to unleash their creativity and bring their design concepts to life with precision and finesse.

Environmentally Friendly:

Water jet cutting is an environmentally friendly cutting method that produces minimal waste and emissions. Unlike traditional cutting methods that use abrasive materials or generate harmful fumes, water jet cutting utilises a stream of water mixed with abrasive particles to cut materials cleanly and efficiently. This eco-friendly approach reduces environmental impact and promotes sustainable manufacturing practices, aligning with the growing emphasis on environmental stewardship in Ipswich and beyond.

High Precision and Accuracy:

Precision is paramount in many industries, where even the slightest deviation can lead to costly errors or compromises in product quality. Water jet cutting offers exceptional precision and accuracy, with tolerances as tight as ±0.1mm. This level of precision ensures that components and parts meet exact specifications, resulting in consistent quality and performance across production runs. Whether it's cutting intricate gaskets, precision components, or intricate artwork, water jet cutting delivers precise results every time.

Fast Turnaround Times:

In today's fast-paced business environment, speed is often of the essence. Water jet cutting services in Ipswich offer fast turnaround times, allowing businesses to meet tight deadlines and stay ahead of competitors. With advanced CNC technology and efficient processes, water jet cutting services can quickly process orders and deliver finished products in a fraction of the time required by traditional cutting methods. This rapid turnaround enables businesses to respond swiftly to customer demands and market trends, driving business growth and profitability.

Water jet cutting services in Ipswich offer a cutting-edge solution for businesses and industries seeking precision, versatility, and efficiency in their cutting operations. With its ability to cut a wide range of materials, minimal material distortion, complex shape cutting capabilities, environmental friendliness, high precision and accuracy, fast turnaround times, and reduced secondary processing, water jet cutting is transforming the way businesses approach cutting and manufacturing processes. By leveraging the power of water jet cutting, businesses in Ipswich can gain a competitive edge and achieve superior results in their cutting applications.

Comments

Post a Comment